In the course of time, expectations regarding tile installation have drastically changed. Today, grout is no longer seen as a mere filler in between tiles. It is a critical component that can affect the durability, hygiene and long-term look. As a result, epoxy grout producers and adhesive sealant manufacturers play an increasing role in shaping how tile systems work in residential, commercial, and industrial settings.

Epoxy grout is widely used due to its strength, resistance to chemicals and is stable in difficult conditions. Contrary to traditional grout made of clay, epoxy-based ones are designed to provide consistent performance in areas where temperature fluctuations, moisture and frequent use can cause degradation.

Research and Engineering as a Foundation of Quality

The research that is conducted leads to high-performance epoxy mortar, not mass-production. Companies that focus on research and development, focus on developing formulas that balance functionality and durability with long-term strength. These formulations can flow into even the narrowest grout lines, then cure to the most dense and non-porous material that resists staining or cracking.

Kastar Adhesive Co.,Ltd specializes in adhesive manufacturing and offers an One Stop Solution Service to assist in the research-driven approach. Through integrating product development and manufacturing capabilities, Kastar Adhesive Co.,Ltd assures that epoxy solutions are designed not just for laboratory use, but also for real world applications.

Engineers with years of experience investigate the way epoxy grout behaves on various surfaces, climates and the installation techniques. This enables manufacturers to design formulations that are durable and reliable even after installation.

Precision Manufacturing and Quality Control

The consistency of performance is crucial for epoxy grout. Manufacturers of epoxy grout rely on the latest equipment used in production to guarantee precise mixing ratios as well as curing and other parameters. This control level ensures that every batch is able to provide the same strength, adhesion, and application properties.

Through the entire manufacturing process the strict quality control systems check performance benchmarks. For distributors and contractors, this assurance reduces the risk of jobsite accidents and removes uncertainties when it comes to sourcing materials for large-scale projects.

It is designed to be versatile Across Applications

Epoxy grout developed by experienced adhesive sealant manufacturers is designed to perform across a wide range of applications. It can be applied to countertops, floors and walls and outdoor surfaces which are exposed to extreme temperatures and chemical substances.

Due to its smooth and well-sealed surface, epoxy grout is a fantastic option for kitchens in commercial settings. Retail areas, healthcare establishments and industrial spaces are all good options. The capacity of epoxy grout to stand up to the harshest conditions makes it an excellent option for outdoor installation. The traditional grouts typically end up failing over time due to their inability.

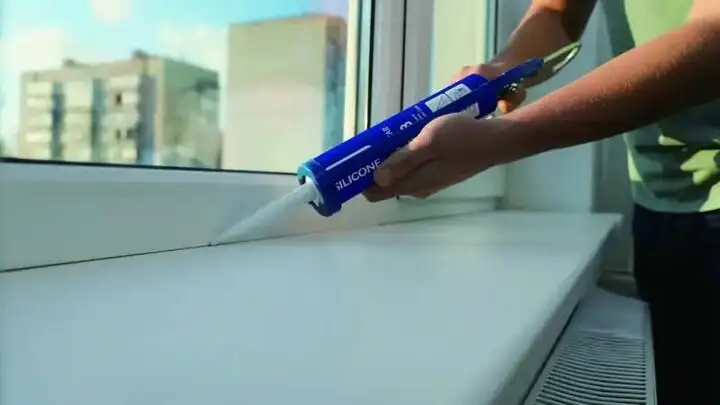

The Importance of Matching Tools and Materials

The performance of grout is tightly tied to how it’s applied. Manufacturers that supply both epoxy grout and the appropriate grout tools understand the importance of system compatibility. Installers will get better results, smoother surfaces, and more consistent results when they use products and tools are designed to be used together.

This approach also improves efficiency on the job site through reducing errors during installation and minimizing waste material. For wholesale or commercial projects, these gains translate directly into cost savings and quicker timelines.

Wholesale and Custom Grout Support

Custom grout solutions are in high demand as construction projects become more specific. The top epoxy grout manufacturers are expanding their capabilities to offer custom formulations that meet specific needs for performance, colors and environmental conditions.

With extensive knowledge of manufacturing adhesive sealants, Kastar offers custom development and huge-scale wholesale supplies. This allows the company to supply residential, commercial retail, industrial, and markets without compromising quality or sturdiness.

The Long-Term Solution for Modern Construction

Epoxy grouts aren’t designed to be a solution for the short term. When designed by experienced epoxy grout manufacturers and supported by a solid research team, precise manufacturing and quality control, it becomes a long-term investment in performance.

Epoxy grout is a material which will continue to be used for projects that require durability, dependability and professional outcomes. This means that tile installations are as effective decades after installation as they were on the first day.